CALL US: 43 (0) 16152990

OUR OPENING HOURS: Mon-Thu 7:00 a.m.-3: 30 p.m. | Fri 7:00 a.m. to 1:30 p.m.

CALL US: 43 (0) 16152990

OUR OPENING HOURS: Mon-Thu 7:00 a.m.-3: 30 p.m. | Fri 7:00 a.m. to 1:30 p.m.

Laser welding

We are there for you - technology and know-how

Stationary laser welding

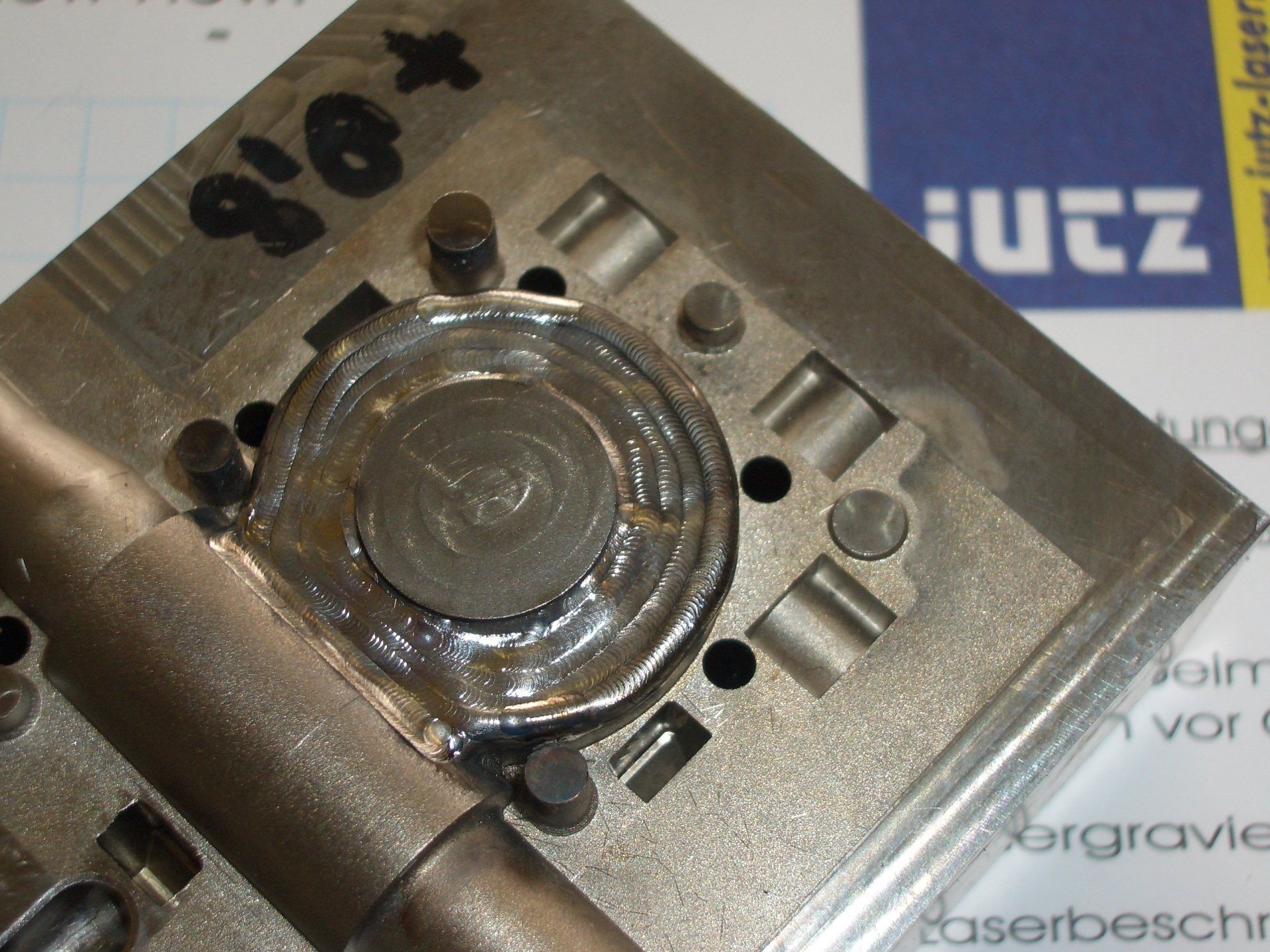

In our service centre in Vienna, Jutz Lasertechnik has more than 20 years of technical expertise and all of the appropriate equipment for laser welding devices to meet your welding requirements.

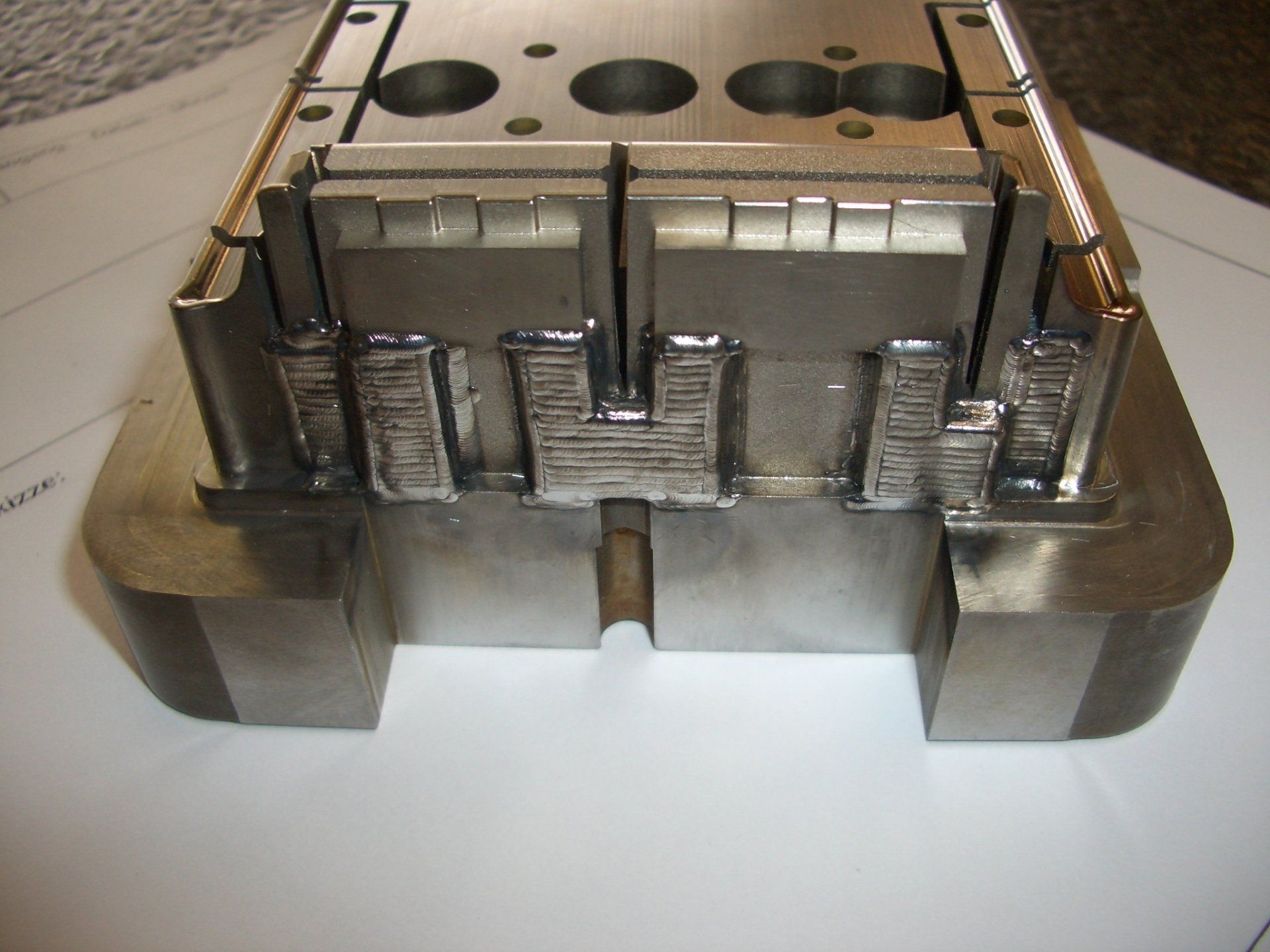

With our ALPHA LASER welding systems and our very well trained technicians, we offer solutions for your applications. We process requests competently, quickly and reliably with the highest quality. Our machine park includes 7 ALPHA LASER welding systems with up to 900W fibre lasers, so we can easily assist with all of your requirements, large or small! When possible, we can complete smaller jobs for you while you wait and we can create machine molds and tools of up to 1000 kg in-house.

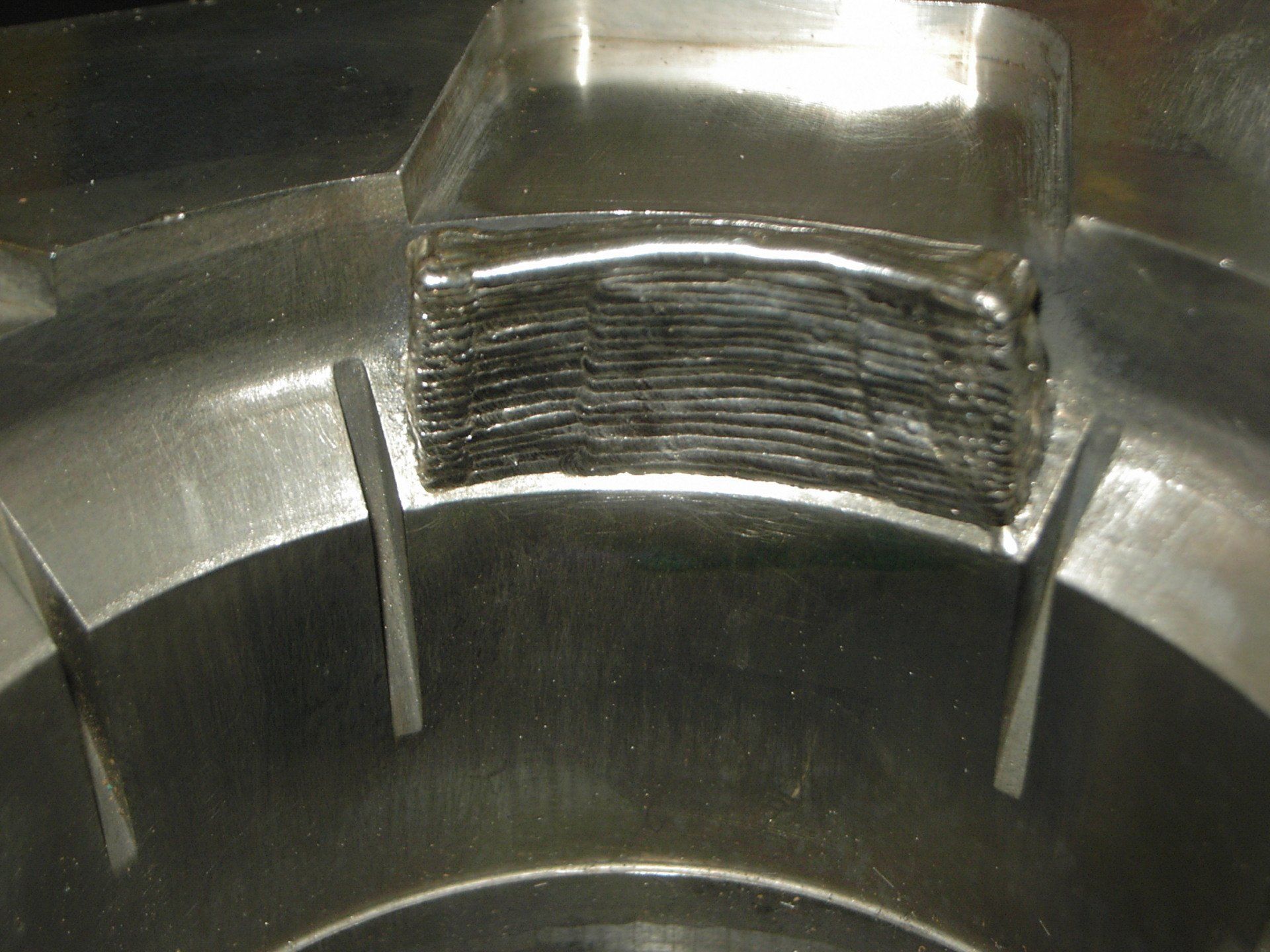

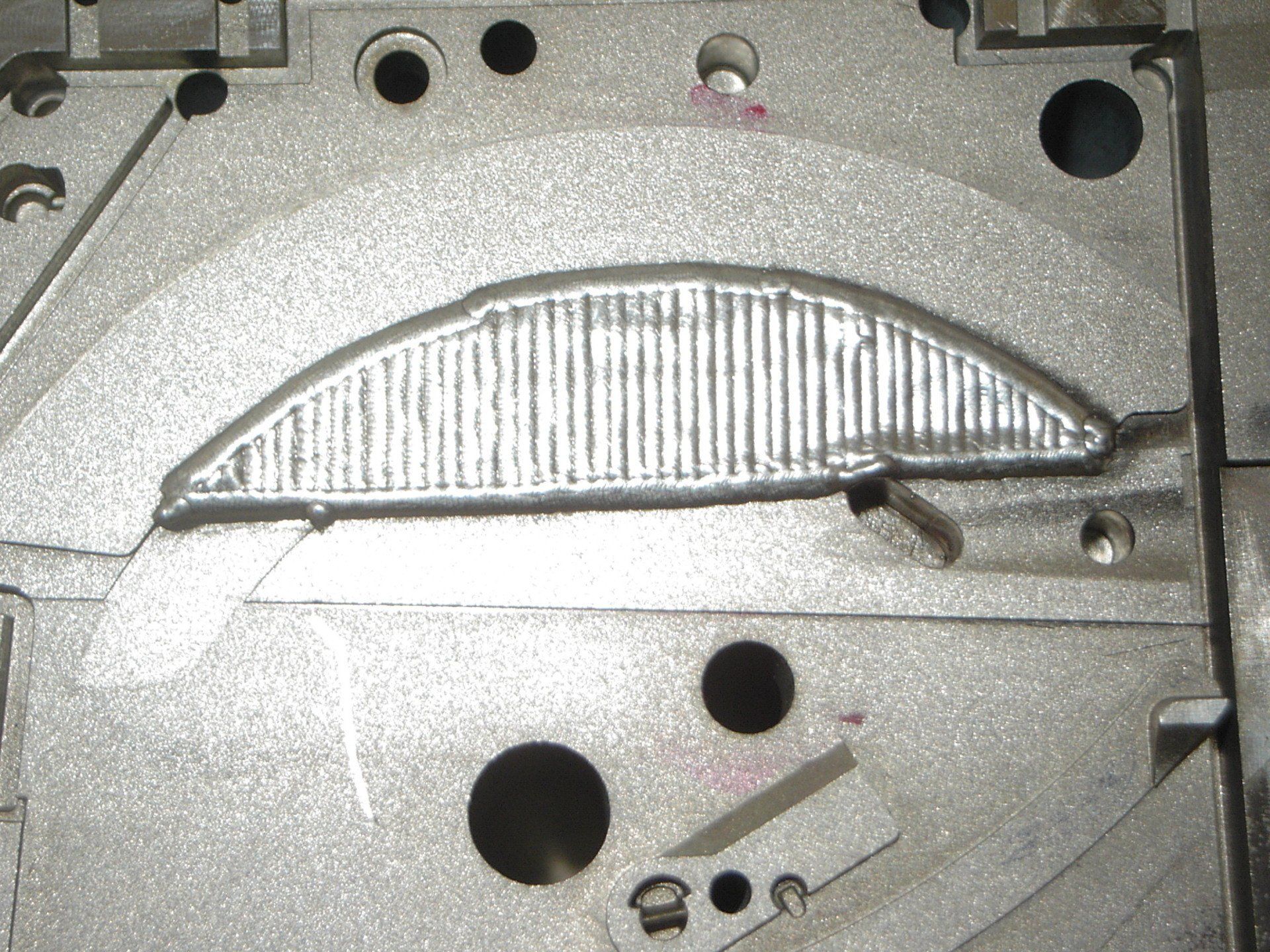

Almost all common materials that are used in toolmaking can be welded (e.g. steel alloys, aluminium, titanium). As the laser systems have been equipped with more and more power in recent years, larger welding volumes can be completed in a short amount of time in a manner that is gentle on the material.

If you need us on site, we will load the ALM onto our mobile emergency vehicle and bring it directly to you. We can count on our many years of experience and help you carry out all your welding tasks.

It is important to us that you are satisfied and receive the quality that you expect. We always look forward to assisting you with your projects or applications. We are your local, certified expert in laser technology.

The advantages of laser welding:

Precise energy input even on the smallest structures

Minimal heat affected zones

High mechanical seam strength

Extremely thin weld seams possible without having to rework

Connection of metals with different melting points possible

Excellent process control for consistent manufacturing quality

Classic areas of application for laser welding:

Contour changes

Correction of worn component geometries

Repairs and changes to mold inserts

Repair of die casting molds

Elimination of defects in cast parts

Repair of heavily or over used functional areas

and much more

Industry sectors for laser welding:

Tool and mold making (repairs and modifications - structural steel and aluminium)

Sheet metal production (stainless steel housing parts - no pickling necessary)

Precision mechanics (micro parts)

Medical technology (surgical tools)

Aerospace (titanium construction - cable connections)

Power plant construction (wear parts on valves - sealing welds)

Mechanical engineering (shaft seats, wear zones, constructions, gear repairs, rollers)

Engine construction (cast aluminum parts, classic car parts)

Automotive industry

Sensor manufacturing

Industrial solutions

Jewellery processing

Dental technology

Weldable metals and their alloys:

Steel

Stainless steel

Molding

Aluminum

Ampco

Titanium

Silver

Gold

Platinum

Inquiries and information to:

info@jutz-lasertechnik.at

We are happy to help!

Give us a call

write us

Visit us at

Laxenburger Straße 218, 1230 Vienna

Contact

Phone: 43 (0) 16152990

Fax: 43 (0) 16152990 - 20

Email: info@jutz-lasertechnik.at

Location

Jutz Lasertechnik GmbH

Slamastrasse 47

A-1230 Vienna

Imprint | Terms of Use | Data protection | Conditions